Control and monitor your asset in real-time!

The tank monitoring solution allows our client to manage and monitor their asset remotely. Spefically liquid( and solid) level control in Tank(stationary and mobile) and Silo can be measured with an 2 mm accuracy.

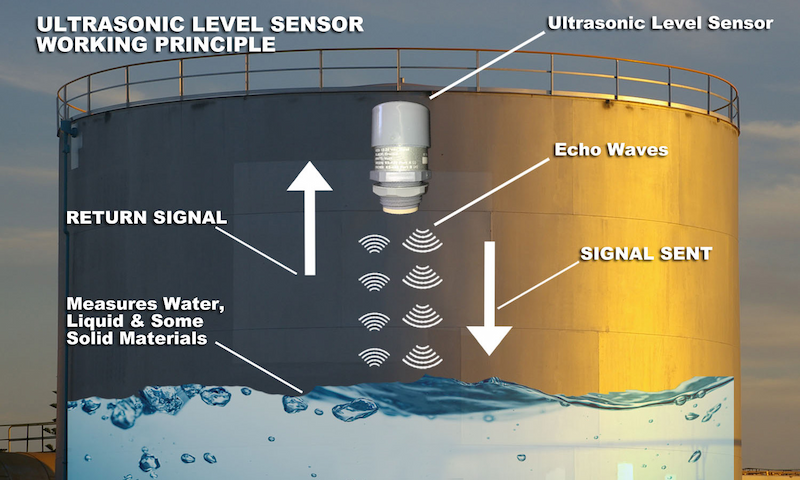

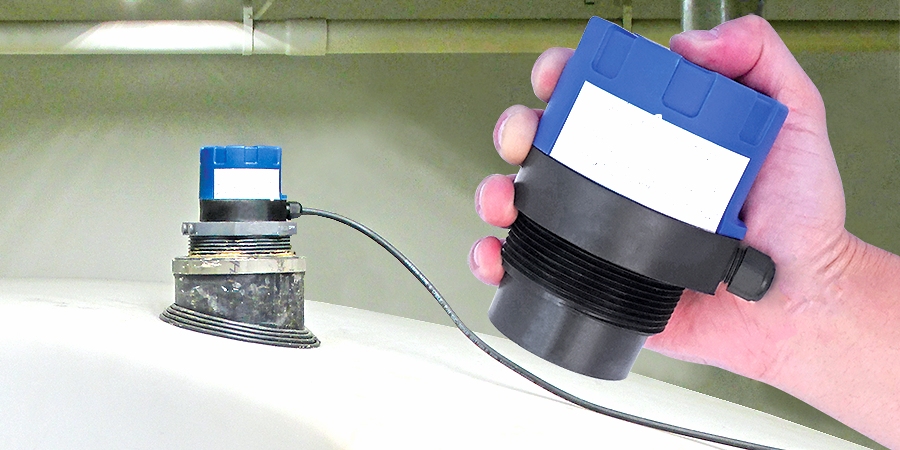

An IoT-based liquid level monitoring solution involves mounting ultrasonic level sensors in your tanks that calculate the fluid's/solid's distance to determine the fluid/solid level and send the data to an IoT gateway.

This data is stored in the cloud and presented on your IoT-based solution dashboard as the fluid/solid level in the tanks. Besides the real-time information on your dashboard, you can get advanced analytics for informed decision-making. Defining threshold limits for the fluid/solid levels allows you to manage inventory as an alert is triggered whenever the level goes below or beyond the prescribed limits.

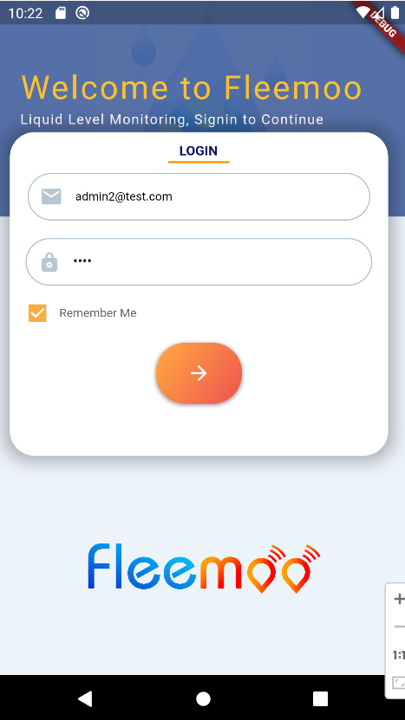

An IoT-based liquid level monitoring solution's dashboard is accessible through desktop and mobile devices, while notifications are sent through the app, SMS, and email.

Start Monitoring Learn more ↓

Base principles of the system.

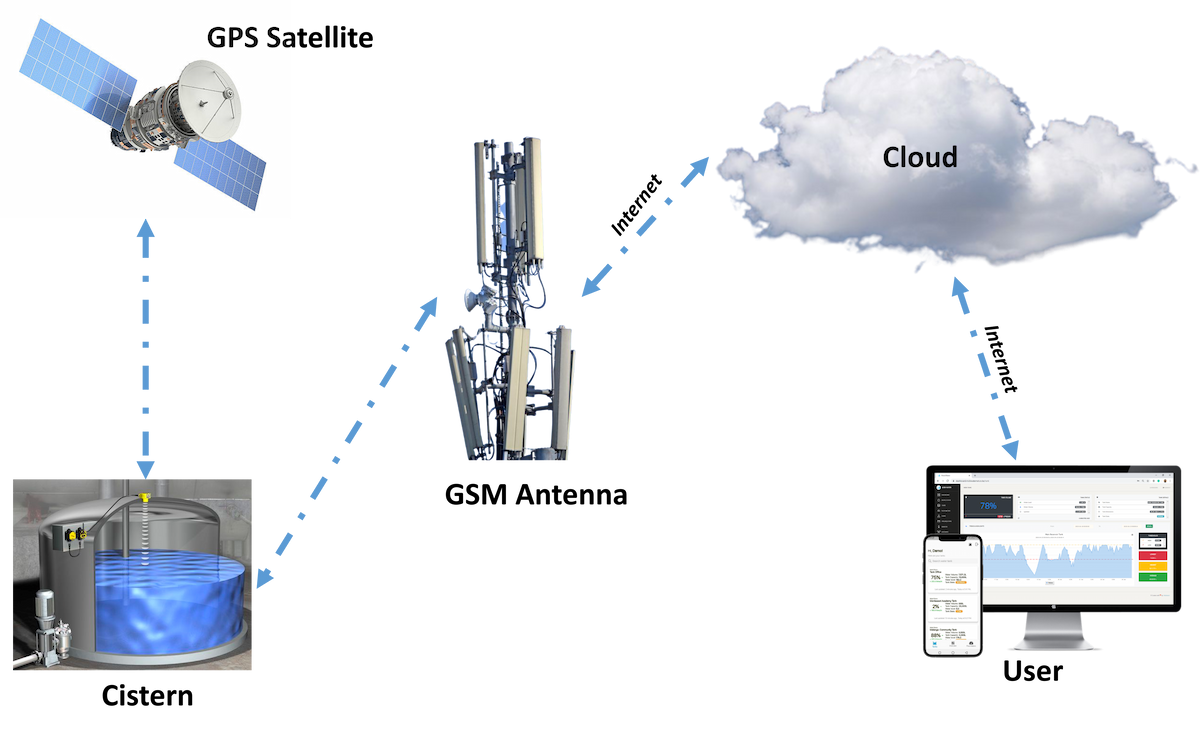

Tank Monitoring System

The sensor do send the measureddata to our backend. the information are compute and send to zour mobile

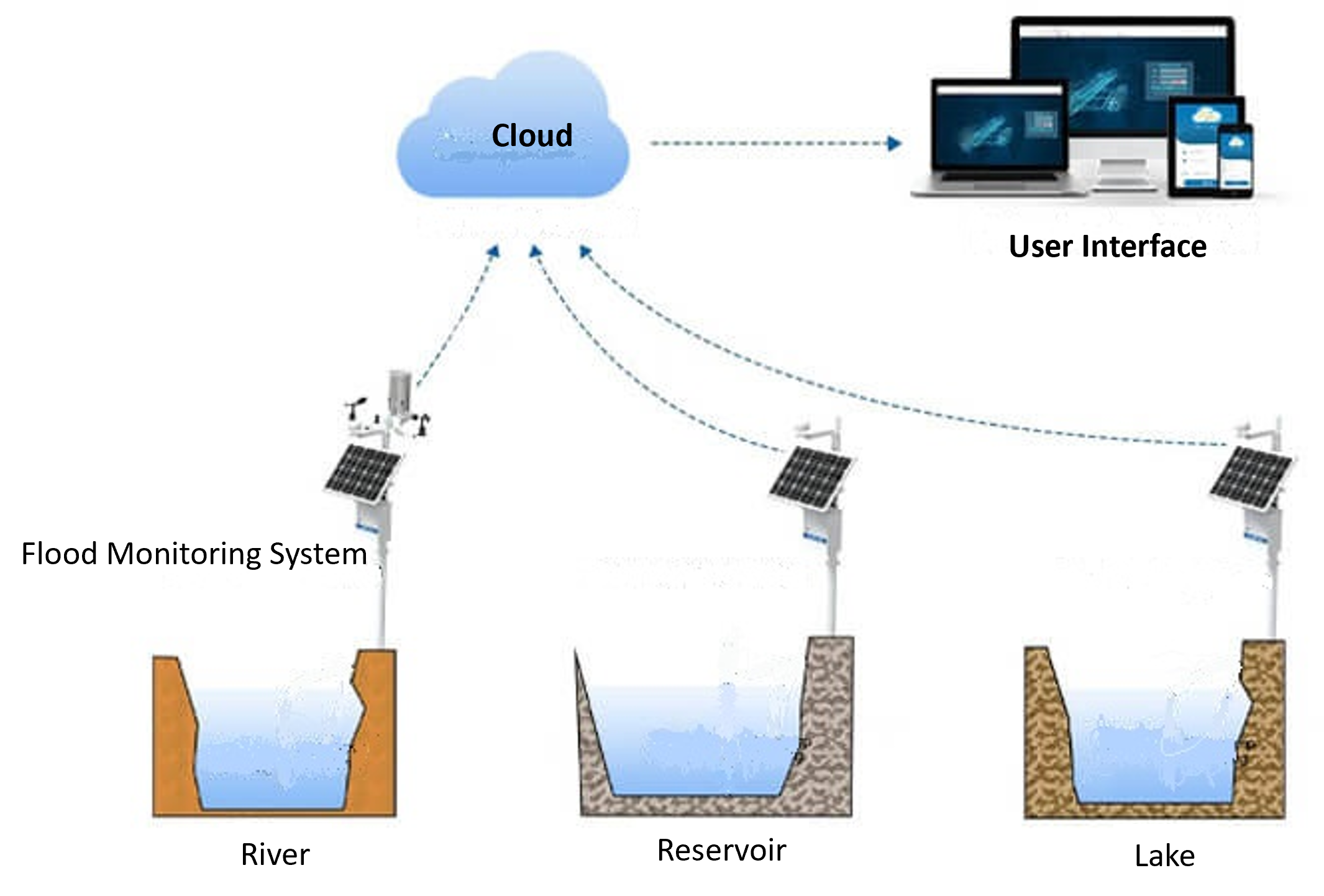

Flood Monitoring System

The system do monitor the level of the water continously. the information are send to our back-end and computer. in case of unsusal rise of teh level, an alarm is send out for evacuations.

Understand the system in 3 simple steps.

01

How the system works.

Contact us over our formular or support hotline and provide the characteristics of your fleet and teh needed serevices.

02

Installation

After clarification and the commercial agreement, our service team will install the required devices. We will launch the system and set the necessary credentials.

03

Enjoy the added values!

We will coach you to use the system at best or provide you a support. that's it. Enjoy the value for your business!

Select the best package for your application

Standard

Level

Remote Level Monitoring up to 1mm accuracy

-

Level Monitoring -

Localization -

Consumuption history -

Leak (theft) detection -

Alarms Notifications

Premium

Level +

additionally to all features of the standard package

-

Consumption Forecast -

User Consumption Behavior -

Activ I/O (e.g. Engine cutt-off) -

Cistern Fleet Management -

Fleet Analytics

PREMIUM +

Flood

Flood Monitoring System

-

Localisation -

River Level Forecast -

Activ I/O (e.g. Engine cutt-off) -

Level Historical Reports -

Alert System

Real Time Monitoring

View on a tailored map the real-time status of your tank with a requested accuracy.

Accuracy

Using different module and technology we can ensure diverse accuracy up to 1 mm

Technology

Integration of different measurements technologies like Ultrasonic, Laser or Gauge.

ML Prediction

Using Machine Learning algorithm, we offer predictive data for upcomming timeframe.

Analytics

Timeframe analytics on Level, consumption rate, alert, etc. comparative analysis of the fleet.

Some Frequently asked questions.

01

What are teh various type of alerts s available?

The raw data is processed to offer the following information

- Fill level alerts

- Theft alerts

- Temperature alerts

02

What is a fill level alert?

These alerts are generated when the fluid level in the tanks exceeds or drops beyond the threshold. You can automate the motor control to ensure the right levels are maintained. So, when the level drops, the motor switches on to maintain inventory levels. Whereas when the level rises, it is switched off to avoid overflow.

03

What is an inventory alert

You can set an alert for the minimum inventory level to ensure you never run out of it. In the case of multiple tanks, the inventory data from all would be calculated to give you the total inventory levels. You can automate the inventory procurement using this information.

04

What's a temperature alert?

Maintaining the temperature of chemicals and flammable liquids is mandatory to avoid accidents. The temperature of liquids may vary due to transit and other external factors such as changes in weather conditions and pressure.

You can set a temperature range and receive notifications upon any deviations in temperature. It helps comply with regulations and prevent accidental fires.

05

Do the technology works with none liquids (such as coffee capsules)?

The ranging ability depends on the material’s reflectance, which has to be a minimum reflective to IR. For example, it is possible with rice. These are different use cases, and you have to consider if you are filling or emptying a jar.

06

Do you offer support to help customers solve issues we are having?

Contact your local support or ask questions on https://www.cisterny.com

07

What's a theft alert?

Controlling the theft of liquids such as water, oil, and fuel is very tough, but an IoT-based liquid level monitoring solution keeps track of your usage data. It alerts you regarding any anomaly, along with the exact data related to the event. You can use the information to prevent theft within premises and during transit.

08

is it possible to measure the liquid inside a container from the outside of the container, provided the container is transparent??

It depends on the transparency of the container, but also the thickness of the container. Crosstalk could be important. Therefore, it is not recommended.

09

What is the impact of the type of liquid (consistency?) (still water, foam)?

Foam and bubbles are easier to range on as there are more reflective surfaces.

10

Is it safe to use these sensors to measure fuel or gas levels?

Yes. With no electrical over-stress and if the sensor is used on the condition described in the datasheet, there should not be any issue. Light IR will not generate spark when used with fuel.

Get involve and contact us!

Simple, efficient and tailored solutions to your need are waiting for you. start a free trial which can be cancel anytime!